Building resilient critical minerals supply chains to propel technological innovation

The MIT Office of the Vice President for Energy and Climate funds eight projects focused on developing impact-oriented solutions for a flexible and secure critical minerals supply.

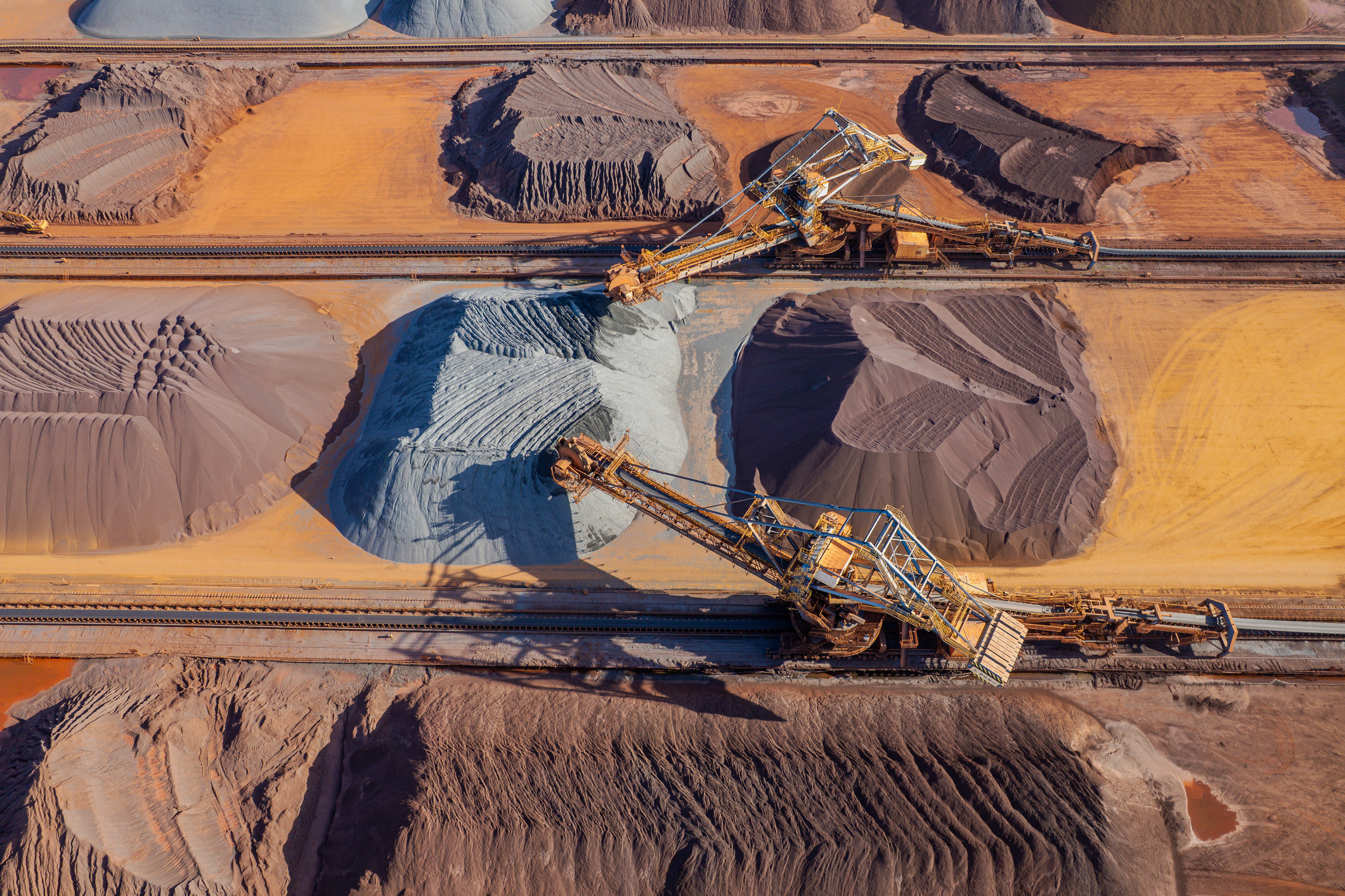

Critical minerals are essential to the production of affordable and abundant energy and defense technologies, as well as the broader global economy — but their supply chains are particularly vulnerable to disruption. Addressing this challenge requires coordinated, comprehensive strategies to strengthen mineral supply through unwavering collaboration across academia, research, industry, investors, and government.

MIT’s Office of the Vice President for Energy and Climate has announced seed award funding for eight projects that are focused on doing exactly that — developing transformative concepts, with impactful collaboration at their core, to address barriers across the supply chain for critical minerals. The winning projects, which are early-stage efforts from principal investigators from across MIT, explore many diverse approaches to securing the critical minerals essential to economic competitiveness and the technological advancements that support both energy resilience and national security. Together, the solutions that are being put forth traverse the wide array of needs that are constantly emerging to advance critical technologies in effective, safe, and sustainable ways.

“As we continue to propel innovations for energy resilience and security, critical minerals are central to these advancements,” says Evelyn Wang, MIT’s Vice President for Energy and Climate. “With next generation, low-carbon technologies requiring increased raw materials, there is an urgent need to grow our supply chain capacity to meet this demand. The opportunity is vast and complex, with many nuances and paths to investigate — and we are inspired by the MIT research teams that have committed to tackling this collectively.”

The seed awards program grew from ongoing discussions among researchers, government affiliates, and industry representatives. The goals of the eight awardees are to identify specific opportunities that are novel and viable at scale and to develop the analysis, experiments, financial models, and external collaborations to attain preliminary results that demonstrate the concept’s feasibility. The teams’ research centers on emergent strategies to bolster long-term supply chain competitiveness and capacity, while also considering the policy and collaboration models needed to support such improvements. The solutions that emerge will build on MIT’s existing strengths in critical minerals and continue to position MIT as a leader in this space.

The winning projects tackle critical gaps across the rare earth supply chain, from developing selective bio-based separation methods and plasma-based reduction processes to closed-loop silicate refining and zero-waste crystallization. They also advance electrified and modular processing methods, design rare-earth-free permanent magnets, and enable recovery from secondary sources like coal fly ash. Together, these efforts integrate materials discovery, process innovation, and techno-economic analysis to deliver scalable, lower-cost, and more sustainable pathways for securing critical mineral supplies.

The project titles and research leads for each of the eight awardees, spanning several aspects of the supply chain, are:

Machine Learning-guided Directed Evolution of Lanthanide-binding Proteins for Enhanced Selectivity in Rare Earth Element Separation, led by Ed Boyden, professor in the Departments of Brain and Cognitive Sciences, Media Arts and Sciences, and Biological Engineering; Y. Eva Tan Professor in Neurotechnology, McGovern Institute, and HHM; and Tanja Bosak, School of Science fundamental science investigator and professor of Geobiology in the Department of Earth, Atmospheric and Planetary Science professor of geobiology in the Department of Earth, Atmospheric, and Planetary Sciences

- This project will use computational tools to analyze natural protein sequences and develop proteins that can capture rare earth elements, creating easier and cleaner ways to extract them.

Plasma Flash Reduction (PFR): A Field-Driven Platform for Refining Rare Earths, Reactive and Refractory Metals, led by Ric Fulop, visiting scientist in MIT's Center for Bits and Atoms (CBA), and Neil Gershenfeld, director of CBA

This project pursues a physics-based approach using novel solid-state plasmas to refine oxides.

A Targeted Machine Learning Approach towards REE Free Permanent Magnets, led by Troy Van Voorhis, Haslam and Dewey Professor of Chemistry in the Department of Chemistry, and Danna Freedman, Frederick George Keyes Professor of Chemistry in the Department of Chemistry

This project uses computer modeling to design new types of magnets that could replace rare-earth magnets, which can eventually be made in the lab.

Low Temperature, Closed-loop Refining of Rare Earth Elements from Silicate Ores, led by Yet-Ming Chiang, Kyocera Professor of Ceramics in the Department of Materials Science and Engineering

This project is testing chemical methods that can pull rare earth elements out of rock in a more selective and efficient way.

Chemical-free Dysprosium Extraction by Capacitive Deionization, led by Martin Z. Bazant, Chevron Professor in Chemical Engineering, Mathematics in the Department of Chemical Engineering

This project is creating rare earth separation methods that avoid chemicals by using charged electrodes to capture and release specific elements used in advanced magnets.

Selective Rare Earth Element Recovery from Coal Fly Ash, led by Timothy Manning Swager, John D. MacArthur Professor of Chemistry in the Department of Chemistry, and Alexander Slocum, Walter M. and A. Hazel May Professor in the Department of Mechanical Engineering

This project is studying how to recover rare earth elements from coal ash by developing membranes made with plastics that catch and release metals in response to electrical stimulation.

Rare-earth Metal Production by Molten Sulfide Electrolysis, led by Antoine Allanore, Heather N. Lechtman Professor and Professor of metallurgy in the Department of Materials Science and Engineering, and Katie Daehn, research scientist in the Materials Research Laboratory

This project is developing electrochemical methods to extract rare earth elements from many sources, ranging from raw ore to recycled products at the end of their life.

Zero-Waste Rare Earth Separation via Reversible Acidity, led by Yogesh Surendranath, Donner Professor of Science in the Department of Chemistry

This project is testing a new process that uses changes in pressure and a reusable chemical to separate and collect rare earth elements.

For more information on any of these projects, please e-mail vpec@mit.edu.